What is our vision?

The North-East Region will become an european technological hub in the textile sector.

What are our objectives?

⁃ The intensification of collaboration between the academic/research sector and private/industrial environment.

⁃ Digital solutions development the missing links in the textile value chain (production, marketing & sales, advertising).

⁃ Local, regional and international partnerships development and innovatiove solutions implementation.

The textile industry is one of the most dynamic economic sectors in North-East Romania, with over 940 companies, 30,000 employees, with a share of 19% of the total textile exports (the second regional exporter of goods). The regional textile industry includes companies producing yarns (long and short staple acrylic, wool, hemp yarns, fancy yarns), woven, knitwear, clothing, decorative textiles and technical textiles. The North-East Region is the national leader in the production of yarns, knitwear, and garments, especially garment design and manufacturing. Apart from large companies (representing approx. 5% of the total number), the rest are SME’s, 70% being involved in apparel production. At the regional level, there is a textile cluster, Astrico North East (that includes producers of yarns, knitwear, and garments) and an association for innovation and sustainable development ReginnovaNE. In Iași, there is one of the most important IT companies in the world – Gemini CAD Systems that creates software dedicated for the textile industry. Another strong point is the presence in the region of the Faculty of Textile, Leather and Industrial Management, “Gheorghe Asachi” Technical University Iași, which is the first and the most important provider of education and knowledge at the national level, as well as research and innovation. The Faculty has a Center for Research for advanced textile materials, with 12 research laboratories covering all textile domains and a doctoral school.

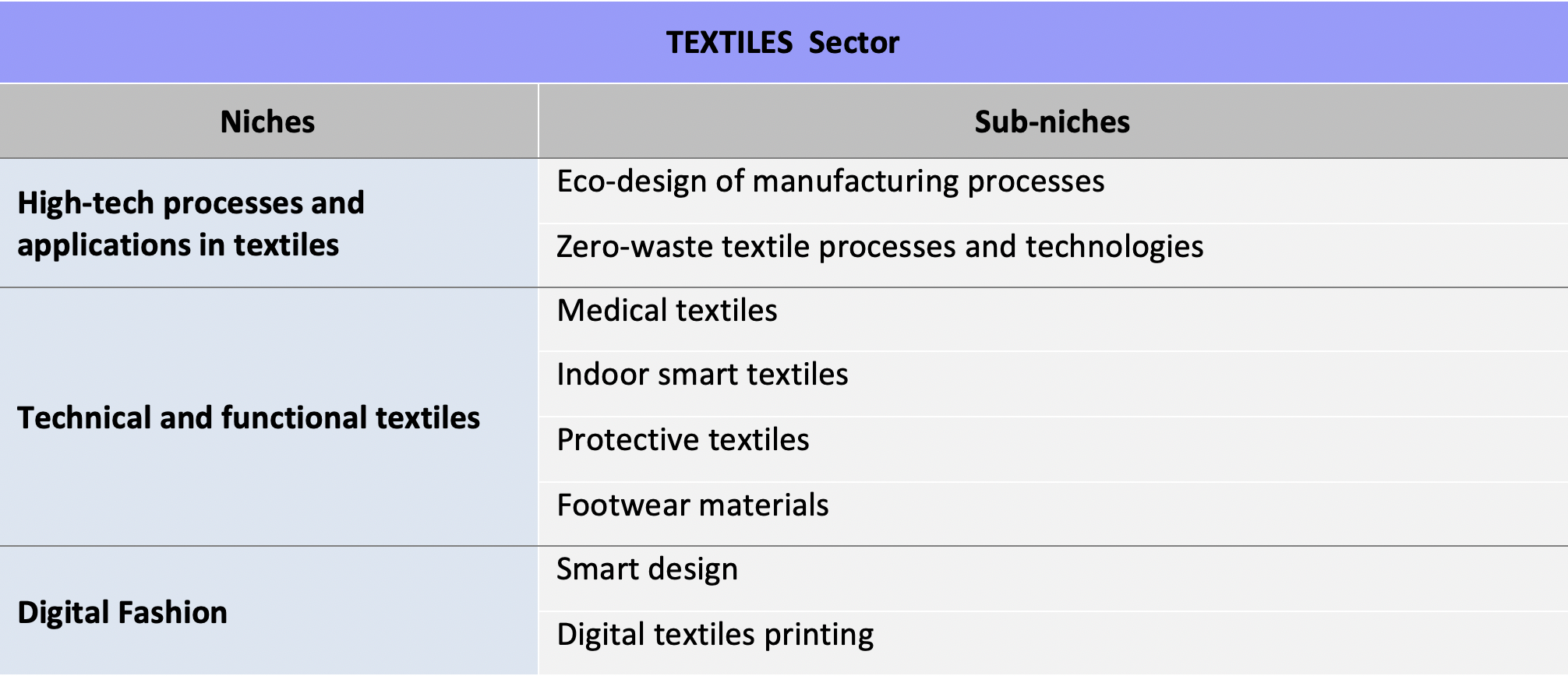

Trends: A positive evolution of the turnover, number of companies and exports of regional textile & clothing industry, but a decrease in the number of employees are observed since 2011. There is also an increase in the level of automation of the textile processes and the use of CAD/CAM systems for the design and production of textile materials and clothing. Also, there are a significant number companies that have started to develop niche markets as a more profitable alternative.